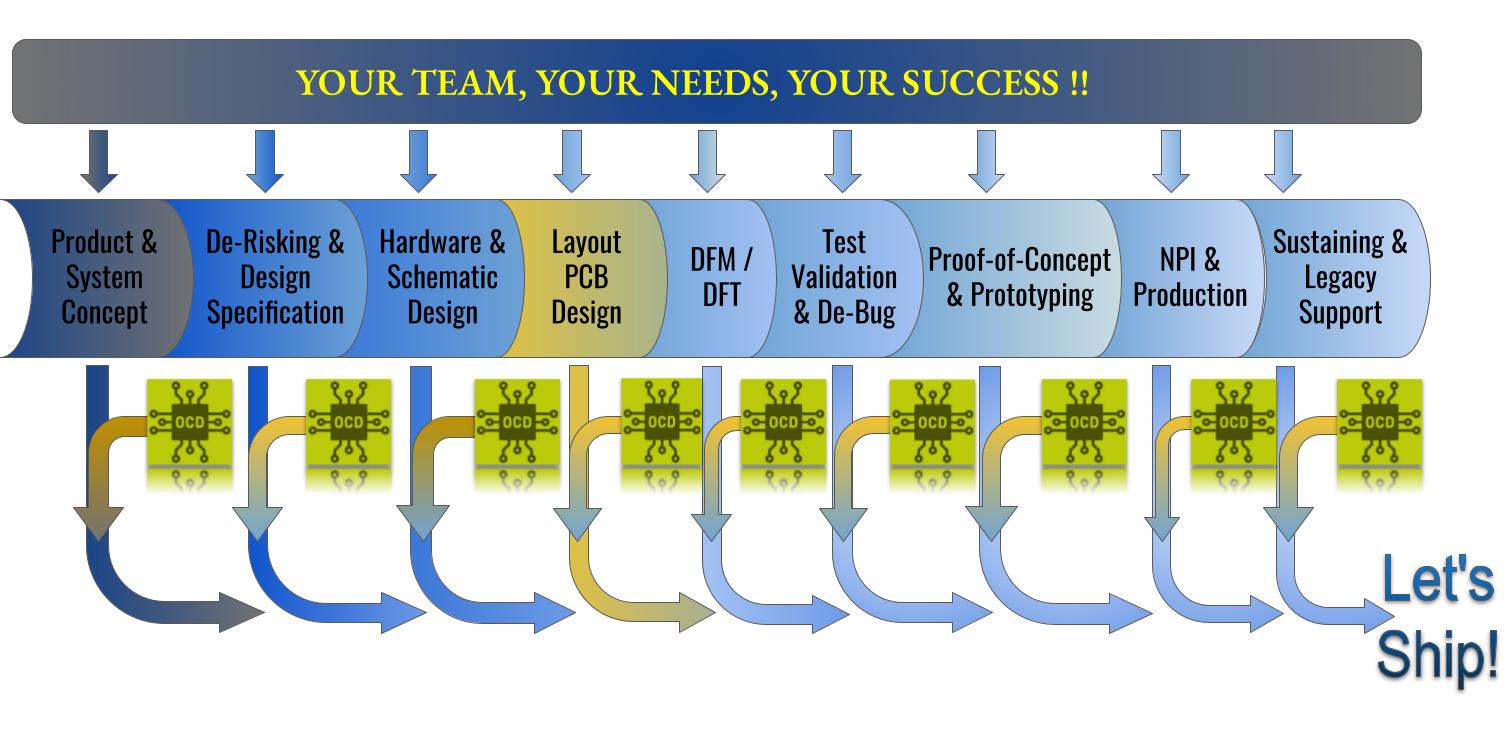

Olivier Courtois Design offers a rich and diverse expertise that covers the different stages of a product design. Restricting ourselves to a specific role has never been our philosophy. Our focus is on overcoming challenges and delivering solutions! Thus, OCd extends it’s fruitful contribution wherever it’s needed to get the job done.

On Demand Resource !

An Electronic Engineer resource where It’s most needed !

You’re in need of an additional resource for your important project ?

You are not able to fill the open position and the schedule keeps slipping ?

Our affordable services add the extra hands you need to meet your delivery dates !

Specialized in PCB Layout Design, OCd provides the same experience and expertise wherever you need it !

Product & System Concept

Product & System Concept

- Product Specifications

- System level Specifications

- Form Factor/Assembly Structure

- Interface Definition

- Firmware/Software Platform

De-Risking Assessment & Hardware Design Specifications

De-Risking Assessment & Hardware Design Specifications

- Critical Parts Assessments

- Hardware Features

- Firm/Soft De-Risking

- MEC constraints

Hardware & Schematic Design

Hardware & Schematic Design

- Schematic Circuit Design

- Procurement Assessments

- BOMs

- Test Plans

PCB Design Layout

PCB Design Layout

- PCBA Design Layout

- MEC Constaints

- Form Factor

- Interfaces

- EMI & Noise Control

- Product Assembly

- DFx

DFM / DFT

DFM / DFT

- PCBA Array Optimization

- Design for Certification

- Mass Production Scalability

- Minimize Vendor Back & Forth

- Quick Turn-Over

- Test Features for PCBA Vendor

- Test Features for Production Testing

- Test Features for Prog. & Debug

Test Validation & De-Bugging

Test Validation & De-Bugging

- Bring-Ups!

- Qualification Tests

- Functionality Tests

- Certification Tests

- Product and System Spec. Validation

- De-Bugging!

Proof-of-Concept and Prototyping

Proof-of-Concept and Prototyping

- Fast Design, Fast Answers!

- Low Volume

- Feature Testability

- Feature Functionnality

NPI & Production

NPI & Production

- Assembly + Testing SOPs

- Testing and Prog. Jig

- Transfert to Production Ing.

- Cost Reduction

- Vendor Assessments

- Production Optimization

Sustaining & Legacy Support

Sustaining & Legacy Support

- Component Engineering

- End-of-Life Components

- Re-Design

- Customization

- Cost Reduction

List of abbreviations

OCd: Olivier Courtois Design

PCB: Printed Circuit Board

PCBA: Printed Circuit Board Assembly

DFM: Design for Manufacturing

DFT: Design for Testing

DFx: Inclusive of all Design For ….

NPI: New Product Introduction

BOM: Bill of Material

MEC: Mechanical

EMI: ElectroMagnetic Interference

SOP: Standard Operating Procedure

Glossary

*** Definitions may vary from one company to another ***

Schematic Design: Design of the electronic circuit drawings.

Layout Design: Creation of the Printed Circuit Board. Materialization of the electronic circuit drawings.

Lead Designer : Person responsible for conducting all the activities around the development of the electronic product. Discipline implication may vary.

Schematic designer: Person responsible for the schematic design. Might also play the role of the Lead Designer.

Prime Designer: Similar to Lead Designer.